Shipping carrier optimization is about moving from choosing carriers by habit (“we always use this one”) to choosing them based on outcomes: cost, speed, reliability, and customer experience.

It’s not about chasing the cheapest label. It’s about building a shipping system that:

- protects your delivery promises,

- reduces exceptions,

- and keeps costs predictable as volume grows.

If you’re shipping at any meaningful scale, optimization isn’t a “nice to have.” It’s how you keep growth from turning into chaos.

What is shipping carrier optimization?

Shipping carrier optimization is the ongoing process of selecting the best carrier and service for each shipment, based on rules, constraints, and real performance data.

That includes:

- picking the best service level (not just the cheapest)

- balancing national + regional carriers

- optimizing by zone, weight, DIM, and destination type

- reducing late deliveries and “where is my order” tickets

- preventing avoidable surcharges and billing surprises

In plain terms: it’s how you turn shipping into a controlled system instead of a daily scramble.

Why shipping optimization gets harder as you grow

At low volume, you can “eyeball” decisions.

At scale, you’re dealing with:

- more SKUs (and weirder packaging profiles)

- more zones and delivery patterns

- more on-site promises (2-day free shipping thresholds, etc.)

- more carrier variability by region

- more surcharge exposure (DIM, DAS, fuel, address corrections)

- more exceptions you have to triage

Optimization gets harder because every new variable multiplies complexity.

What you optimize for (it’s more than just cost)

Most teams say “we want cheaper shipping,” but the best operators optimize across four outcomes:

1) Cost per shipment (fully loaded)

Not just base rate, real landed shipping cost, including:

- fuel

- residential/DAS

- DIM adjustments

- peak fees

- address corrections

- surcharges that show up later on the invoice

2) On-time delivery performance

This is the silent profit killer. Late deliveries create:

- refunds/discounts

- reships

- higher support volume

- reduced repeat purchase

3) Exception rate (and the cost of handling exceptions)

Lost packages, damages, missing scans, delays, and failed delivery attempts, these drain time and margin.

4) Customer experience

Customers don’t care which carrier you used.

They care that it arrives when you said it would, with clean tracking and minimal drama.

The carrier optimization maturity curve

Most teams move through stages:

Stage 1: Cheapest label wins

- Rate shop, print label, cross fingers, and hope it arrives.

- Works until volume rises or exceptions spike.

Stage 2: Rules-based selection

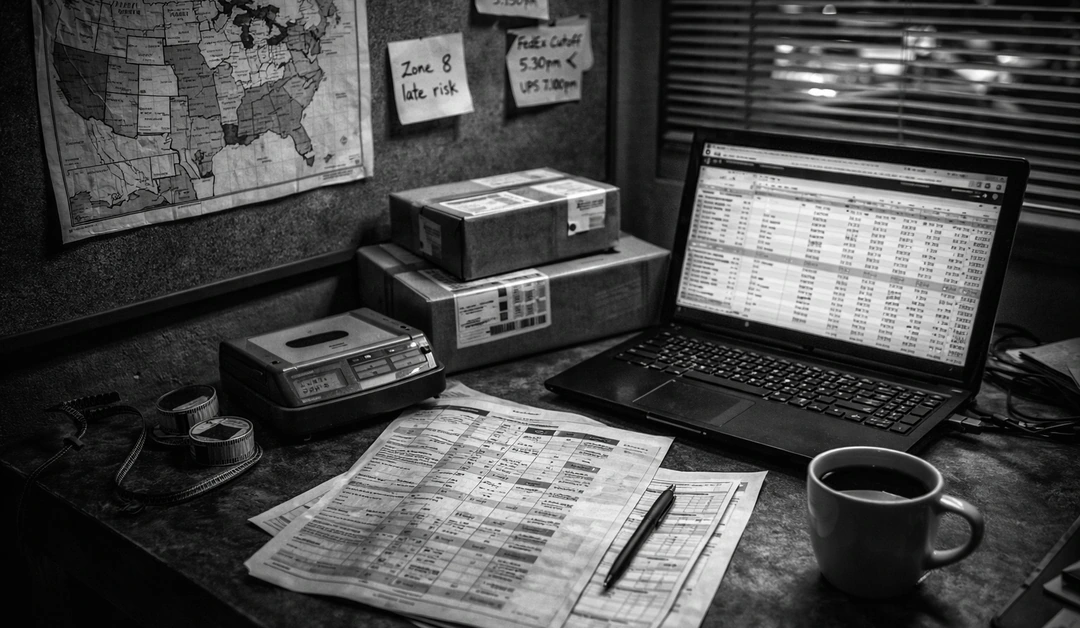

- Simple rules like “under 1 lb goes USPS,” “Zone 8 use Carrier X.”

- Better, but still limited.

Stage 3: Performance-informed optimization

- Rules start factoring in actual delivery performance by zone, service, warehouse, and time period.

Stage 4: Real-time orchestration

- Your shipping system dynamically routes shipments based on cost + service-level protection + current constraints (cutoffs, outages, capacity, backlog).

The goal is not “perfect routing.” The goal is stable performance and predictable cost as conditions change.

9 practical ways to optimize shipping carriers (that actually work)

1) Start with a clean baseline: your shipping mix

Pull a 30–90 day snapshot:

- shipments by carrier and service

- zones and delivery regions

- billed weight vs actual weight

- DIM impact by SKU or carton

- exception types and frequency

If you don’t know your starting point, every “optimization” is just vibes.

2) Optimize service levels (this is usually the fastest win)

Most overspending happens here:

- using 2-day when Ground would deliver in 2 days anyway

- using premium services for “peace of mind”

- overcorrecting for a small % of late orders

A simple improvement:

- map “expected Ground delivery days” by zone/region

- create guardrails: “upgrade only when risk exceeds X”

3) Use regionals where they outperform nationals

Regional carriers often win on:

- specific lanes

- speed consistency

- cost (especially for heavier parcels or dense metro areas)

The trick is not “add regionals.”

It’s: add them where they’re measurably better and keep everything else unchanged.

4) Build zone-aware rules (don’t treat every destination the same)

Carriers don’t perform equally across every zone.

Routing rules that usually outperform generic rate shopping:

- carrier/service by zone

- carrier/service by warehouse and cutoff time

- separate logic for metro vs rural

5) Reduce DIM pain with packaging logic

DIM doesn’t care about your intent.

Optimization isn’t only carrier choice, it’s also:

- cartonization rules

- pack logic (“don’t ship air”)

- SKU packaging data hygiene

A 1–2 inch box change can make a surprising difference in cost and efficiency.

6) Protect your delivery promises with “service-level guardrails”

If your site promises 2–3 days, you need routing logic that protects it.

Guardrails examples:

- “Only choose services with >X% on-time in this zone”

- “Auto-upgrade if order is late to cutoff”

- “Fallback to carrier B if carrier A is degraded”

This is how you stop optimization from becoming customer pain.

7) Treat exceptions like a metric, not an annoyance

Most companies track cost per shipment.

Fewer track exception cost per shipment.

Track:

- late deliveries (%)

- claims rate (%)

- missing scans (%)

- customer contacts per 100 shipments

Then optimize to reduce the total cost of shipping, not just postage.

8) Standardize tracking events and customer comms

Even when delivery is fine, messy tracking causes:

- “where is my order” tickets

- cancellations

- anxiety-driven refunds

Carrier optimization should include:

- normalized tracking statuses

- proactive exception alerts (when possible)

- consistent customer updates

9) Audit invoices and stop paying for preventable mistakes

Even with good routing, margin leaks from:

- service-level mismatch

- incorrect billed weight

- duplicate charges

- address corrections you could have prevented upstream

You don’t need to dispute every line item.

You do need visibility into the patterns.

The KPIs that actually show optimization is working

If you only track “average cost per label,” you’ll miss the point.

Use a simple scorecard:

- All-in cost per shipment (including surcharges)

- On-time delivery % (by zone + service)

- Exception rate % (late, lost, damaged)

- WISMO tickets per 100 shipments

- Cost per order delivered on time (optional but powerful)

- % shipments routed by rules vs manual overrides

Common mistakes that make “optimization” backfire

Optimizing for cost only

Cheaper shipping that increases late deliveries isn’t cheaper. It just moves cost into support and refunds.

Switching carriers too often

Constant changes create operational whiplash. Optimization should be stable, measurable, and intentional.

Rules that nobody owns

If routing logic isn’t governed, it becomes a junk drawer. Somebody has to own rules, tests, and changes.

No feedback loop

Optimization without performance feedback is just set-it-and-forget-it guessing.

Where shipping carrier optimization is heading

The future isn’t more dashboards.

It’s smarter decisions at label time, based on:

- real performance data

- dynamic constraints

- service-level protection

- cost controls that account for surcharges and risk

That’s the difference between basic multi-carrier shipping and what we call carrier orchestration: continuous coordination of carriers, services, and data to protect outcomes (cost + delivery performance) in real time.

FAQ

Is shipping carrier optimization only for high-volume brands?

No. It’s for complexity—multiple warehouses, higher AOV, heavy DIM exposure, tighter delivery promises, or frequent exceptions.

Do I need multiple carriers to optimize?

Not strictly, but optimization is limited with only one carrier. Most meaningful gains come from having at least two viable options per major lane.

What’s the fastest win?

For most teams: service-level optimization + zone-aware rules.

Closing thought

Shipping carrier optimization is not a one-time project. It’s a system: measure → route smarter → monitor outcomes → refine rules.